RepRap was founded in 2005 by Adrean Bowyer, a Senior Lecturer in mechanical engineering at the University of Bath in England. Funding was obtained from the Engineering and physical research council.

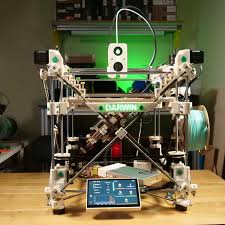

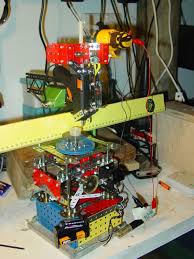

On 13 September 2006, the RepRap 0.2 prototype printed the first part identical to its own, which was then substituted for the original part created by a commercial 3D printer. On 9 February 2008, RepRap 1.0 "Darwin" made at least one instance of over half its rapid-prototyped parts. On 14 April 2008, RepRap made an end-user item: a clamp to hold an ipod to the dashboard of a Ford festa car. By September that year, at least 100 copies had been produced in various countries. On 29 May 2008, Darwin achieved self replication by making a complete copy of all its rapid-prototyped parts (which represent 48% of all the parts, excluding fasteners). A couple hours later the "child" machine had made its first part: a timing-belt tensioner.

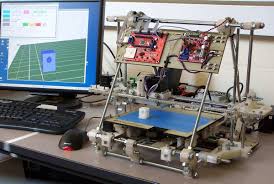

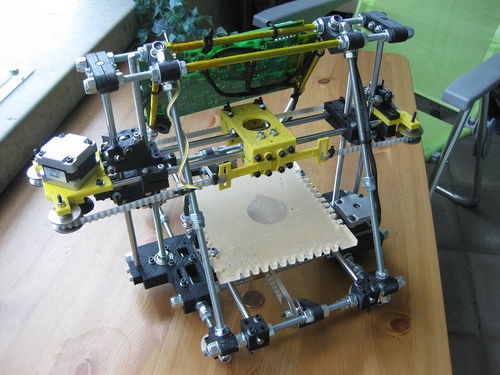

In April 2009, electronic circuit boards were produced automatically with a RepRap, using an automated control system and a swappable head system capable of printing both plastic and conductive solder. On 2 October 2009, the second generation design, called Mendel, printed its first part. Mendel's shape resembles a triangular prism rather than a cube. Mendel was completed in October 2009. On 27 January 2010, the Foresight Institute announced the "Kartik M. Gada Humanitarian Innovation Prize" for the design and construction of an improved RepRap.

On 31 August 2010, the third generation design was named Huxley. It was a miniature of Mendel, with 30% of the original print volume. Within two years, RepRap and RepStrap building and use were widespread in the technology, gadget and engineering communities.

In 2012, the first successful Delta design, Rostock, had a radically different design. The latest iterations used Open beams, wires (typically Dyneema or Spectra fishing lines) instead of belts, and so forth, which also represented some of the latest trends in RepRaps.

In early January 2016, RepRapPro (short for "RepRap Professional", and one commercial arm of the RepRap project in the UK) announced that it would cease trading on 15 January 2016. The reason given was congestion of the market for low-cost 3D printers and the inability to expand in that market. RepRapPro China continues to operate.

Hardware

As the project was designed by Bowyer to encourage evolution, many variations have been created. As an open source project, designers are free to make modifications and substitutions, but they must allow any of their potential improvements to be reused by others.

In 2023 the youtuber Vector 3d designed the RepRap Evo to celibrate 23 years of RepRap and gave it away to someone at SMRRF (Sanjay Mortimer RepRap Festival). It was based on the orijanal RepRap darwin and folows the design path of the voron trident.

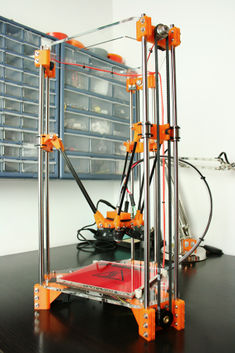

There are many RepRap printer designs including:

Prusa i3

Hang printer

RepRap Fisher

Reprap Snapy

RepRap Morgan

Reprap Ormerod

RepRap Darwin

and RepRap Mendel

Glue gun reprap

(Sorce of info RepRap wiki)